© 2024 Johnson Battery Company, ALL RIGHTS RESERVED.

SUSTAINABILITY

BUILDING A CIRCULAR ECONOMY

BATTERY RECYCLING

All spent batteries recycled through Johnson Battery Company are sent to East Penn Manufacturing for proper recycling. Our customers have the critical reassurance of safe battery recycling without the worry of debilitating fines, penalties, or paperwork associated with hazardous waste disposal laws. A Regulatory Notice is provided to our customers which documents the pick-up and proper recycling of every spent battery.

Since day one, East Penn has made safe recycling an everyday practice. East Penn opened its doors as a battery rebuilding company almost three-quarters of a century ago. Today, the company has never stopped building on its expertise, infrastructure, capabilities, and commitment. This continuous commitment has made East Penn the most progressive manufacturer in environmental protection and technologically advanced battery recycler throughout the entire industry.

LEAD

Our highly efficient smelting facility provides lead required in the manufacture of our new products. It is fully compliant with Environmental Protection Agency and the Pennsylvania Department of Environmental Protection standards. Excess heat from our furnace is redirected through a radiator system to warm adjacent manufacturing facilities in cold weather. Sulfur fumes generated during the smelting process are captured and reprocessed into a liquid nitrogen sulfur solution. Over 24,000 tons of this solution is sold to make fertilizer for agricultural use each year.

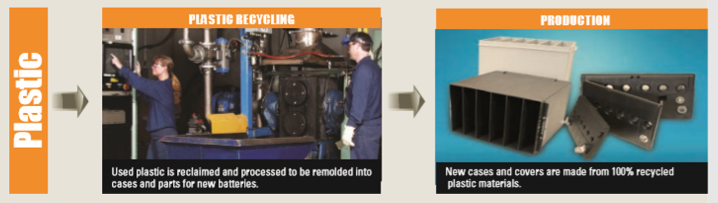

PLASTIC

Polypropylene (plastic) is also recycled. Battery cases and covers are cleaned, ground, and re-extruded into polypropylene pellets. The material is then blown through a pipe network to our on-site injection molding facility where it is molded into new cases and parts.

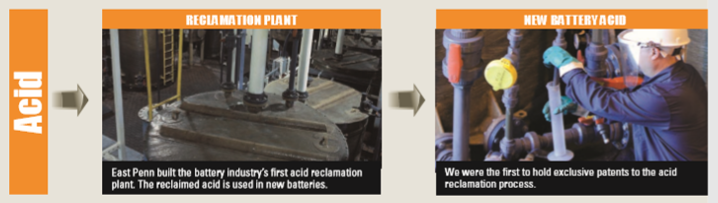

ACID

East Penn scientists invented the patented process that reclaims sulfuric acid from spent batteries for use in new energy storage devices. At the acid reclamation facility, the first of its kind in our industry, heavy metals and other impurities are removed and the solution is converted into a new electrolyte, diverting this material from potentially hazardous disposal.

Johnson Battery Company also provides recycling capabilities for nickel-cadmium batteries. Our fleet of delivery trucks and professional drivers allows for easy pick-up and transportation of used batteries for recycling.

WASTE STREAM MANAGEMENT

Managing our waste stream is more than just good business – it is our responsibility to the communities that we serve and operate. And at Johnson Battery Company we take this responsibility very seriously. Our customers and employees can be proud to partner with a company that implements industry-leading processes to reduce our waste and ensures that any waste created is properly handled to reduce or eliminate any environmental impact.

ENVIRONMENTAL SAFETY & MANAGEMENT

EAST PENN SUSTAINABILITY

STACKING & SECURING USED BATTERIES

Stationary Power Packaging and Securing Stationary Batteries Cells (PDF)

SUSTAINABILITY REPORT

Sustainability Report 2023

LEAD

Our highly efficient smelting facility provides lead required in the manufacture of our new products. It is fully compliant with Environmental Protection Agency and the Pennsylvania Department of Environmental Protection standards. Excess heat from our furnace is redirected through a radiator system to warm adjacent manufacturing facilities in cold weather. Sulfur fumes generated during the smelting process are captured and reprocessed into a liquid nitrogen sulfur solution. Over 24,000 tons of this solution is sold to make fertilizer for agricultural use each year.

PLASTIC

Polypropylene (plastic) is also recycled. Battery cases and covers are cleaned, ground, and re-extruded into polypropylene pellets. The material is then blown through a pipe network to our on-site injection molding facility where it is molded into new cases and parts.

ACID

East Penn scientists invented the patented process that reclaims sulfuric acid from spent batteries for use in new energy storage devices. At the acid reclamation facility, the first of its kind in our industry, heavy metals and other impurities are removed and the solution is converted into a new electrolyte, diverting this material from potentially hazardous disposal.

Johnson Battery Company also provides recycling capabilities for nickel-cadmium batteries. Our fleet of delivery trucks and professional drivers allows for easy pick-up and transportation of used batteries for recycling.

WASTE STREAM MANAGEMENT

Managing our waste stream is more than just good business – it is our responsibility to the communities that we serve and operate. And at Johnson Battery Company we take this responsibility very seriously. Our customers and employees can be proud to partner with a company that implements industry-leading processes to reduce our waste and ensures that any waste created is properly handled to reduce or eliminate any environmental impact.

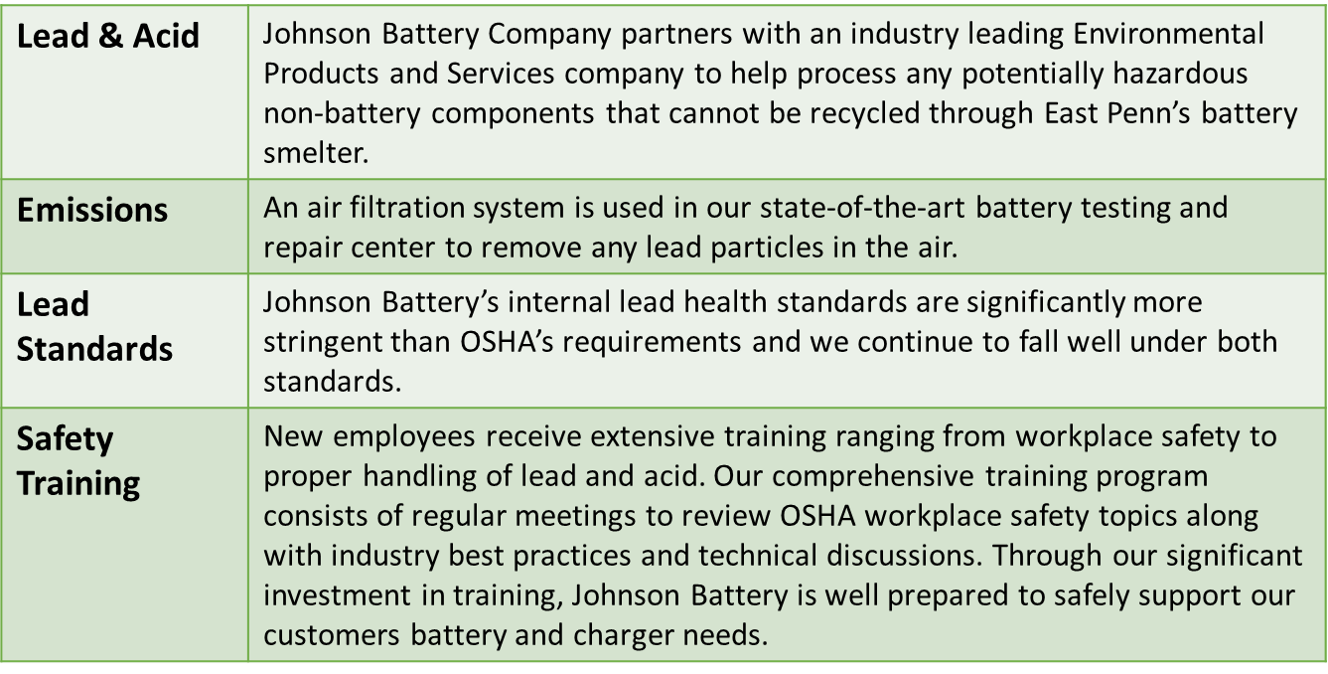

ENVIRONMENTAL SAFETY & MANAGEMENT

ZEBULON

6487 Highway 19 South

Zebulon, GA 30295

(770) 567-0968

LOGANVILLE

164 Line Street

Loganville, GA 30052

(770) 567-0968

JACKSONVILLE

6973 Highway Avenue, Suite 301

Jacksonville, FL 32254

(904) 786-9161

LAKELAND

4300 South Frontage Road, Suite 5

Lakeland, FL 33815

(863) 616-1550

POMPANO BEACH

1571 West Copans Road, Suite 101

Pompano Beach, FL 33064

(954) 522-2471

BIRMINGHAM

5520 Eastcliff Industrial Blvd.

Birmingham, AL 35210

(205) 497-3899

Johnson Battery Company, Inc.

© 2024 Johnson Battery Company, ALL RIGHTS RESERVED.

Also serving the Caribbean and Latin America.